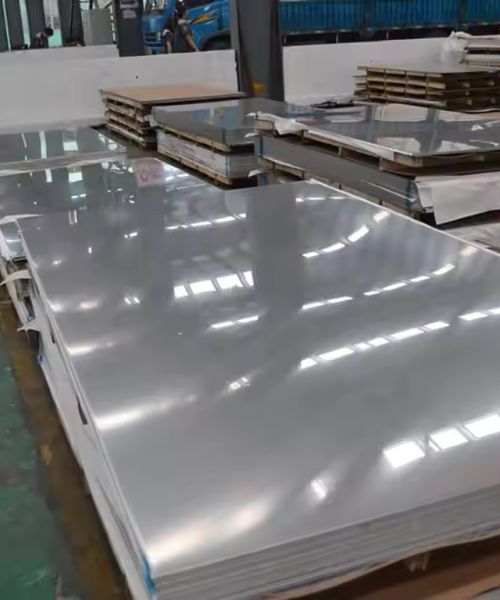

SS 317/ 317L Sheet and Plates

SS 317/ 317L Sheet and Plates Stainless Steel 317 / 317L Sheets & Plates in both domestic and international markets. Our inventory includes a wide variety of surface finishes, sizes, and customized dimensions. Engineered with top-grade materials and manufactured using state-of-the-art technology, these sheets and plates are known for their corrosion resistance, strength, and dimensional accuracy. What is Stainless Steel 317 / 317L? Stainless Steel 317 is an austenitic chromium-nickel steel alloy containing molybdenum, which provides enhanced resistance to chemical attacks. 317L is the low carbon version of 317, allowing improved weldability and minimizing the risk of carbide precipitation during welding. These materials are designed for applications demanding superior corrosion resistance in aggressive environments, especially where chlorides and other halides are present. Key Features of SS 317 / 317L Sheets & Plates Excellent corrosion resistance in acidic and chloride-rich environments High tensile and yield strength Superior formability and weldability Resistance to pitting and crevice corrosion Ideal for high-temperature applications Long service life and robust performance specifications Standards Designation ASTM A 240 ASME SA 240 STANDARD UNS WERKSTOFF NR. SS 317 S31700 1.4449 SS 317L S31703 1.4438 Stainless steel grade 317L is a low carbon version of grade 317 stainless steel Sheets. It has the same high strength and corrosion resistance as 317 steel but can produce stronger welds due to the low carbon content. The following datasheet provides an overview of stainless steel grade 317L. Chemical Composition The chemical composition of grade 317L stainless steel Plates is outlined in the following table. Element Content (%) Iron, Fe Balance Chromium, Cr 18-20 Nickel, Ni 11-15 Molybdenum, Mo 3-4 Manganese, Mn 2 Silicon, Si 1 Phosphorous, P 0.045 Carbon, C 0.03 Sulfur, S 0.03 Mechanical Properties The mechanical properties of grade 317L stainless steel Sheets & Plates are displayed in the following table. Properties Metric Imperial Tensile strength 595 MPa 86300 psi Yield strength 260 MPa 37700 psi Modulus of elasticity 200 GPa 29000 ksi Poisson’s ratio 0.27-0.30 0.27-0.30 Elongation at break (in 50 mm) 55% 55% Hardness, Rockwell B 85 85 Other Designations Equivalent materials to grade 317L stainless steel are given below. AISI 317L ASTM A167 ASTM A182 ASTM A213 ASTM A240 ASTM A249 ASTM A312 ASTM A774 ASTM A778 ASTM A813 ASTM A814 DIN 1.4438 QQ S763 ASME SA240 SAE 30317L Value-Added Services Offered To meet custom industrial demands, we offer several fabrication and post-processing services, including: Cutting (Laser/Plasma/Water Jet) Bending & Rolling Minor Fabrication & Welding Heat Treatment Forging Quality Assurance & Testing Every sheet and plate undergoes rigorous testing as per international quality standards: Tests Conducted Positive Material Identification (PMI) Intergranular Corrosion (IGC) Test Hardness Test Flaring and Flattening Test Micro & Macro Test Third-party Inspection on Request Packaging Details To ensure damage-free delivery, we provide strong packaging: Wooden crates Plywood boxes Plastic wrapping with edge protection Custom labeling Equivalent Grades Standard Grade ASTM A167, A240, A312, A213 ASME SA240, SA213 DIN 1.4449 (317), 1.4438 (317L) SAE 30317L AISI 317 / 317L Applications of Stainless Steel 317 / 317L Sheets & Plates Stainless Steel 317/317L is used in critical industries including: Petrochemical & Chemical Processing Equipment Laboratory and Pharmaceutical Equipment Pollution Control Systems Food and Beverage Processing Heat Exchangers and Condensers Pulp & Paper Industry Ready to Ship, Wherever You Need Reliable Supplies for your next big project? Whether you’re based in India or shipping internationally, we’re here to make sourcing simple. We supply across the USA, Canada, Australia, Germany, Brazil , and the United Kingdom. Fast quotes, custom sizes, and bulk orders available. Let us know what you need—we’ll take care of the rest Supplies from Different Countries Supplies from Different Countries Flag Country Code 🇮🇳 India IN 🇺🇸 United States US 🇬🇧 United Kingdom GB 🇨🇳 China CN 🇯🇵 Japan JP 🇩🇪 Germany DE 🇮🇹 Italy IT 🇹🇷 Turkey TR 🇦🇪 United Arab Emirates AE 🇸🇦 Saudi Arabia SA 🇶🇦 Qatar QA 🇴🇲 Oman OM 🇰🇼 Kuwait KW 🇦🇺 Australia AU 🇨🇦 Canada CA 🇳🇱 Netherlands NL 🇮🇩 Indonesia ID 🇪🇬 Egypt EG

SS 317/ 317L Sheet and Plates Read More »